Space

While the estimation of the electrical and data cables’ lifetimes is crucial for satellites and other spacecraft, mid-life checks are expensive and uncommon in space applications. To address this need, Nordisch offers a simulation tool for the service life prediction (SLP) of cables, thermal control blankets, thermal interface materials, and exterior spacecraft/satellite surfaces that exposed to high doses of Gamma radiation due to the lack of an atmosphere to serve as an absorbing medium.

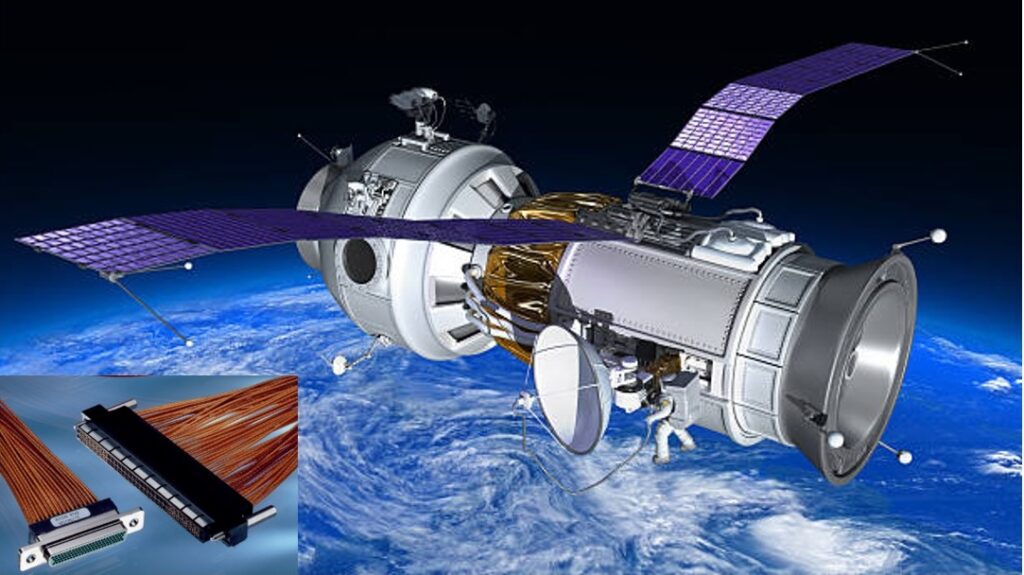

It will be necessary for spacecraft vehicles and satellites to function over a wide temperature range and must be able to withstand regular (and frequently rapid) thermal cycling (from -230C to 250C), as well as the exhaustion and intense radiation that comes with it. Electrical wire/cable aging can cause satellite systems to malfunction (partially or totally), but it’s difficult to forecast when this would happen in systems built for harsh environments like orbit. Experimental research cannot realistically recreate all potential operating circumstances in space orbit. In space structures, due to the severe conditions that exist in low earth orbit (LEO), polymer degradation occurs in exterior spacecraft/satellite surfaces, thermal control blankets, solar arrays, cables, electronic coatings, and adhesively bonded radiator surfaces.

Each orbit and deep space mission has its challenges. Examples of damage accumulated that accelerates the aging of cables and components that can jeopardize the mission of operation are:

- Atomic oxygen exposure in the Earth’s atmosphere at the low Earth orbit application

- High radiation along with extreme thermal shock at external flying cable and connector in geosynchronous earth orbit.

Nordisch LLC is making significant investments in technologies and systems intended to operate in complex and challenging space environments. Our solution to this challenge is Multiphysics simulation software named NordRad. NordRad3.0 is a customized version of NordRad that was developed for space applications. It is a framework that (1) predicts damage accumulation in polymers induced by coupled thermal and radiative loads, and (2) establishes a link between real-time aging and accelerated thermal-radiative aging tests.

Our customer can use NordRad3.0 to generate reliable data to assess (i) the current performance and (ii) the remaining service-life (RUL) of the cables in real time. NordRad3.0 ability to monitor residual damage in operating cables without disconnecting the cables, thermal blankets, and exterior spacecraft/satellite surfaces can save significant time and cost and secure the mission.