of cables/wires, O-rings, and rubber parts used in the nuclear reactors.

Addressing the need for the license renewal of nuclear power plants.

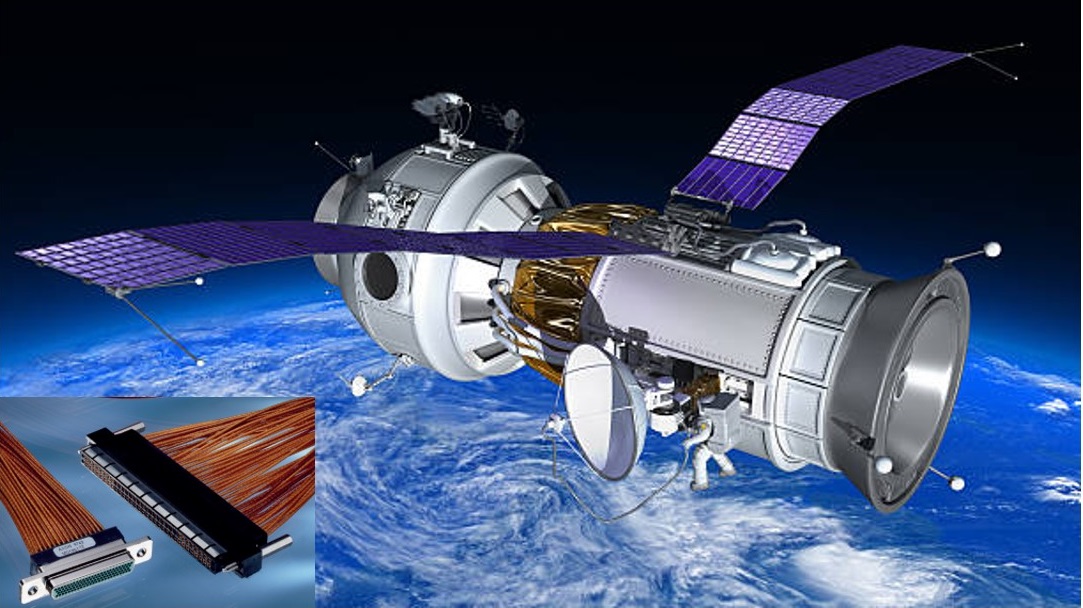

of cables, thermal control blankets, thermal interface materials, solar arrays, electronic coatings, and exterior spacecraft/satellite surfaces.

of cables/wires, rubber, O-rings and adhesives in the aircraft.

Damage assessment of polymer composite aircraft structures resulting from excessive heat exposure

of polymers, adhesives and thermal interface materials (TIM) at the electronic industry.

Simulation Tool for the Reliability and Determining Remaining Useful Life of Cables, Plastics, Elastomers, Adhesives, and Composites.

Our Multiphysics software delivers solutions to assess the current performance, and determine the remaining service life (RUL) of polymer and composite parts used in a broad range of industries such as nuclear, space, aviation, and military industries. This helps our customers to deliver durable products, mitigate risk, and avoid the cost of unexpected failures.

Industries

Aviation Sector

A simulation tool to assess the current performance and to determine the Service Lifetime of:

- Polymer composite aircraft structures exposed to transient heat and ultra-long thermal oxidation

- Cables/wires, rubber, adhesives, & O-rings parts under combined multivariable stressors (oxidation, thermal cycle, hydrolysis, dynamic bending & static loads)

This secures the efficient and safe passage of electrical and power signals between the electrical components of the aircraft, which is essential for the continued safe functioning of the aircraft after its planned lifespan.

Nuclear Energy

A simulation tool to assess the current performance and determine the Service Lifetime of cables/wires, O-rings, and rubber parts used in the nuclear reactors at NPPs (nuclear power plants).

With over 86% of nuclear power plants operating beyond their original 40-year license period, the operations’ safety and reliability have become a subject of significant attention. Our simulation tool can be used for the license renewal of NPPs by determining the SLP of polymers used in these components. This is a framework that (1) predicts damage accumulation in polymers induced by coupled thermal and radiative loads, and (2) establishes a link between real-time aging and accelerated thermal-radiative aging tests.

Space Sector

A Simulation tool to assess the current performance and to determine the Service Lifetime of cables, thermal control blankets, thermal interface materials, solar arrays, electronic coatings, and adhesively bonded radiator surfaces and exterior spacecraft/satellite surfaces exposed to high doses of Gamma radiation.

In space applications, mid-life inspections are rare and costly, and due to the severe conditions that exist in low earth orbit (LEO), polymer degradation in real-time can be modeled with our simulation tool.

Oil & Gas, and Petrochemical Industries

Nordisch LLC addresses the critical challenges of polymer aging in the Oil, Gas, and Petrochemical industries with NordPoly, our advanced simulation tool. Designed to predict the service life of components like O-rings, packers, and protective coatings, NordPoly models the effects of sour gas, brine, high pressure, and extreme temperatures. By tackling issues like thermal-oxidative aging, chemical corrosion, and mechanical degradation, NordPoly empowers industries to enhance safety, extend component lifecycles, and reduce maintenance costs in the world’s most demanding environments.

Products

NordTIM

A solver for Thermal Aging + Mechanical Deformation:

Using an AI-driven continuum model, NordTIM is a three-dimensional kinetic solver that helps our customer to address their product design and development challenges for Thermal interface materials (TIMs) used in electronic boards. The solver predicts oxidative degradation rates in combined mechanical-thermal environments. The solver can also be used for Miniaturization in microelectronics which is an essential step in the compaction process of any electronic system.

NordRad

A solver for Thermal + Radiation Aging + Mechanical Deformation:

Using an Al-driven continuum model, NordRad is a three-dimensional kinetic solver that predicts oxidative degradation rates in combined radiation-thermal environments. Thermal oxidation, Alpha, Betta & Gamma radiation, together with mechanical deformations, are different environmental stressors that can concurrently be applied to the materials to specifically predict the performance loss of polymers. Limited data is required to train the model, and then the model has the capability to simulate the different time and aging conditions.

NordPoly

A solver for Thermal Aging + Crack Formation + Vibration:

NordPoly is an Al-driven high-performance high-fidelity finite element aging analyzer with nonlinear capabilities specifically designed to calculate the loss of performance over certain periods for samples exposed to multiple combinations of degradation through thermal aging vibration that has the capability to predict crack formation in the polymers.

NordDLO

A solver for Diffusion Limited Oxidation (DLO) and Heterogenous Aging: Our experimental analysis has shown most of the oxygen will be consumed on the surface layer of the material, especially at high temperatures, which creates a protective layer that prevents the core of the material from being affected by oxidation.

Services

Reliability Analysis & Remaining Life Estimation

We help our customers to uncover any potential product defects during the product design phase, verify the production quality during the production phase, improve the overall product quality, and determine the current performance and remaining service life of polymer parts.

Consultation & Supports

Our technical team at Nordisch will provide consultation service to your project if you have limited time/resources or need the training to solve your engineering challenges. You can use our engineering service starting with some simple initial characterizations on your current (aged) materials and your virgin/unaged materials to determine current performance of your polymeric parts.

Training

Nordisch provides training to our customers to boost the productivity of your employees by giving in-field practical experiences. Depending on the type of your applications and requirements, you will receive training byproducts through real-world case studies.