Reliability Analysis & Remaining Life Estimation

We help our customers to uncover any potential product defects during the product design phase, verify the production quality during the production phase, improve the overall product quality, and determine the current performance and remaining service life of polymer parts.

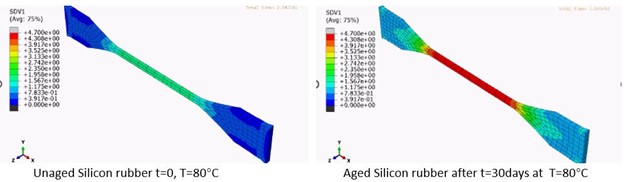

While the use of polymeric and composite systems in different sectors and applications provided durable components with improved resistance to vibration and extreme environment, maintaining the long-term integrity of polymer and composites systems is a primary challenge in aging platforms.

Long-term environmental/ mechanical damage accompanied by damage induced by harsh environmental conditions drastically reduces the materials’ mechanical performance and reliability and may even lead to catastrophic failures. Since most of these aging damages can hardly be detected through viral inspections, in the design of those components, such incidents are often covered by the employment of large safety factors in service-life estimations. This leads to reduced readiness level of fleet and high maintenance costs.

Our team at Nordisch is able to develop an individual model to assess the current performance and predict service life of your materials with respect to different damage applied on your materials. The model is customizable physics-based predictive tools to describe damage accumulation and eventually damage capacity in polymers and composite materials that are concurrently exposed to a combination of mechanical and environmental stressors.

To maximize the value of measured data through rapid analysis and collaborative data sharing.

To design a reliable product that satisfies customer’s expectations in terms of durability, performance over time, and regulatory requirements.

To make the right material choice for right environments to deliver the required products performance.

To understand product service life and performance loss to reduce costs and avoid unexpected failures.